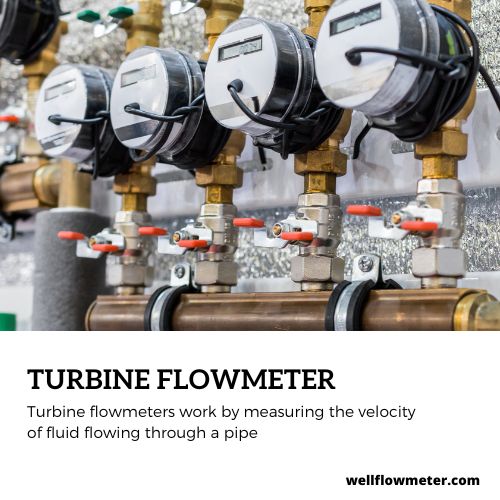

Turbine flowmeters work by measuring the velocity of fluid flowing through a pipe. A rotor with blades is mounted in the center of the pipeline and spins as fluid flows past it. The rotational speed of the rotor is proportional to the fluid velocity, so by measuring the rotational speed, the flow rate can be calculated. Turbine flowmeters can measure a wide range of flow rates and are particularly well suited for measuring high flow rates.

Some benefits of turbine flowmeters include:

– Turbine flowmeters are highly accurate, with an accuracy of +/- 0.05% for liquids and +/- 0.15% for gases.

– Turbine Flowmeters have a wide dynamic range and can measure flow rates from 0.005 to 100 ft/s (0.15 to 30 m/s).

– Turbine flowmeters are repeatable and have a low pressure drop, making them ideal for use in closed loop control systems.

If you’re looking for an accurate and reliable way to measure the flow rate of liquids or gases, a turbine flowmeter may be the perfect solution for you! Contact us today to learn more about our turbine flowmeter products and how they can benefit your application.

Keywords: Turbine Flowmeter, Accuracy, Repeatability, Low Pressure Drop, Closed Loop Control Systems.